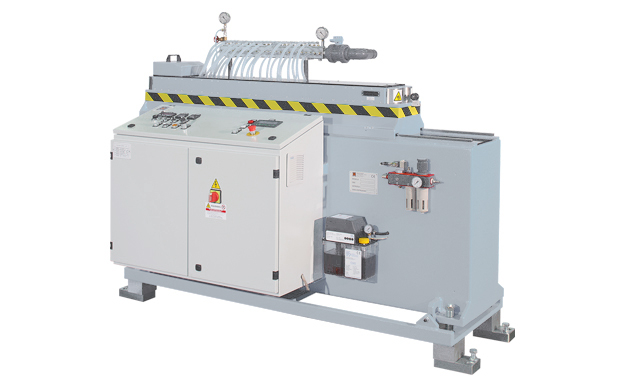

Single Wall Corrugator – FORM 15 -70

The Form 15-70 Single Wall Corrugator is a cutting-edge extrusion machine designed and manufactured by ITIB India to meet the demanding needs of the plastic pipe manufacturing industry. With its precision engineering, superior build quality, and remarkable capabilities, this corrugator stands as a testament to ITIB’s commitment to innovation and excellence.

Datasheet

| SPECIFICATIONS | Units | Value |

|---|---|---|

| Overall Dimensions Weights | ||

| Length | mm | 1550 |

| Width | mm | 1000 |

| Minimum Height | mm | 1200 |

| Weight | Kg | 600(without mold) |

| Technical Data | ||

| Extrusion Axis Height (Standard) | mm | 1050+/-20 |

| Environmental Ranges | ||

| Operating Temperature | °C | 5÷40 |

| Operating Humidity (maximum:) | % | 95 |

| Chain Length | mm | 1980 |

| Closing Length | mm | 700 |

| No of Moulds | Pcs | 70 |

| Consumptions Installed power | ||

| Installed Power | kW | 1,5 |

| Voltage | V | 230-400 |

| Current Frequency | Hz | 50-60 |

| Auxiliary Circuit Voltage | V | 24dc |

| Water Temperature | ˚C | 6-8 |

| Water Consumption | LT/H | 2000 |

| Air System Working Pressure | bar | 7 |

| Air Consumption | Nm³/h | 15 |

| Vacuum Pump (OPTIONAL for V Range only) | ||

| Pumping Speed / Sucking Power | M³/H | 150/175 |

| Workable Pipes | ||

| Standard Diameters (minimum: ID ) | mm | 4.5 vacuum |

| Standard Diameters (maximum: OD) | mm | 15 |

| Output | ||

| PVC (Kgs/Hr) | ±10% | 33 |

| PP (Kgs/Hr) | ±10% | 23 |

| HDPE (Kgs/Hr) | ±10% | 23 |

| Mechanical Speed (maximum) | m/min | 40 |

| Colour | RAL | 7035-7016 |

The Outputs shown are based on theoretical figures and will therefore depend on the type of material used, pipe diameter being produced, ambient temperature, pipe profile and extruder capacity.

ITIB India reserves the right to make any modifications to the machine without prior notice to improve the performance, with no commitment to updating this document.

Features and Benefits:

- Versatile Molding: With 70 molds at your disposal, you have the flexibility to produce a wide range of corrugated pipes, meeting diverse industry demands.

- Energy Efficiency: The Form 15-70 operates on just 1.5 kW of power, helping you reduce energy costs while maintaining high production rates.

- Precision Extrusion: The extrusion axis’s precise height control ensures consistent pipe quality, minimizing waste and maximizing your yield.

- User-Friendly Interface: Its user-friendly design and controls make it easy for your operators to set up, monitor, and adjust production parameters.

- Reliability: Crafted with durable materials and backed by ITIB’s reputation for quality, this corrugator is built to withstand the rigors of continuous operation.

- Output Consistency: Achieving remarkable output rates with a ±10% accuracy margin ensures consistent and reliable production.

- Optional Vacuum Pump: For enhanced performance in specific applications, an optional vacuum pump with a pumping speed of 150 M³/H and sucking power of 175 is available (V Range).

Applications:

The Form 15-70 Single Wall Corrugator is ideal for manufacturing single-wall corrugated pipes with standard diameters ranging from 4.5mm ID to 15mm OD. It accommodates materials such as PVC, PP, and HDPE, making it a versatile choice for various industries, including construction, infrastructure, and telecommunications.