Essential Role of Corrugator Pipe Machines in India

Introduction

The corrugated pipe extrusion line is an indispensable tool for the manufacturing of corrugated pipes, which are increasingly in demand across various industries in India. The Pipes are known for their flexibility, light weight, strength, anti-corrosiveness, and excellent insulation properties. Corrugated pipes are mandatory in numerous applications. The role of corrugated pipe extrusion lines in meeting this growing demand is pivotal, as they ensure the production of high-quality pipes efficiently. This blog post examines the importance of these machines in the Indian context, exploring their features, advantages, applications, and the leading manufacturers in the country.

1. Importance of Corrugated Pipe Extrusion Machines in India

In India, the surge in demand for corrugated pipes across different industries is noteworthy. Corrugated pipe extrusion lines are central to this growth, providing a streamlined manufacturing process that guarantees the production of superior quality pipes. These machines are not just manufacturing tools; they represent a technological advancement that supports various sectors, ensuring a steady supply of essential components for diverse applications.

2. Key Features of Corrugator Pipe Machines

Corrugated pipe extrusion line, as offered by ITIB India, come with a range of features that cater to different production needs. These machines are available in variants like Single Wall Corrugators and Double Wall Corrugators, handling pipes from 4.5mm I.D. to 75mm O.D. They are designed for working with various thermoplastic materials including PE, PP, PVC, PA, and EVA. The technical specifications of these machines, such as machine type, capacity, automation grade, and production capacity, are tailored to meet diverse industrial requirements, ensuring versatility and efficiency.

3. Advantages of Using Corrugated Pipe Extrusion Lines

The utilization of ITIB corrugator in manufacturing brings several advantages. They are known for their low maintenance costs, reduced power consumption, and rugged construction. These attributes not only ensure the production of high-quality pipes but also contribute to the cost-effectiveness and overall efficiency of the manufacturing process. This makes them an ideal choice for businesses looking to optimize their production capabilities.

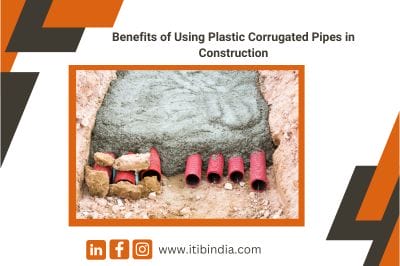

4. Applications of Corrugated Pipes in Different Industries

Corrugated pipes are versatile and find applications in various industries. Their use spans across construction, agriculture, automobiles, white goods like washing machines, vacuum cleaners, sanitary & plumbing, drainage systems, sewerage, and transportation. This versatility underscores the importance of corrugated pipes in the development and maintenance of these critical sectors, highlighting the need for efficient and reliable corrugator pipe machines.

5. Prominent Manufacturers of Corrugated Pipe Extrusion Lines in India

ITIB India stands out as a leading manufacturer of corrugated pipe extrusion line in India. With over five decades of experience, ITIB India has established itself as a trusted name in the industry, offering innovative solutions and adhering to international quality standards. Their expertise, product range, and commitment to customer satisfaction make them a go-to source for businesses seeking reliable corrugator.

Conclusion

Corrugator play a crucial role in India’s plastic pipe manufacturing sector, especially in the production of corrugated pipes. Their importance cannot be overstated, as they not only meet the growing demand for these pipes but also ensure the production is efficient, cost-effective, and of high quality. By understanding the features, advantages, applications, and identifying reliable manufacturers like ITIB India, businesses and individuals can make informed decisions to meet their specific requirements.