The Role of Corrugated Pipes in Indian Sewage Systems

Corrugated pipes have become a crucial component of modern sewage systems, particularly in India. Their versatility, durability, and cost-effectiveness make them an ideal choice for managing the extensive and complex sewage networks required in both urban and rural areas.

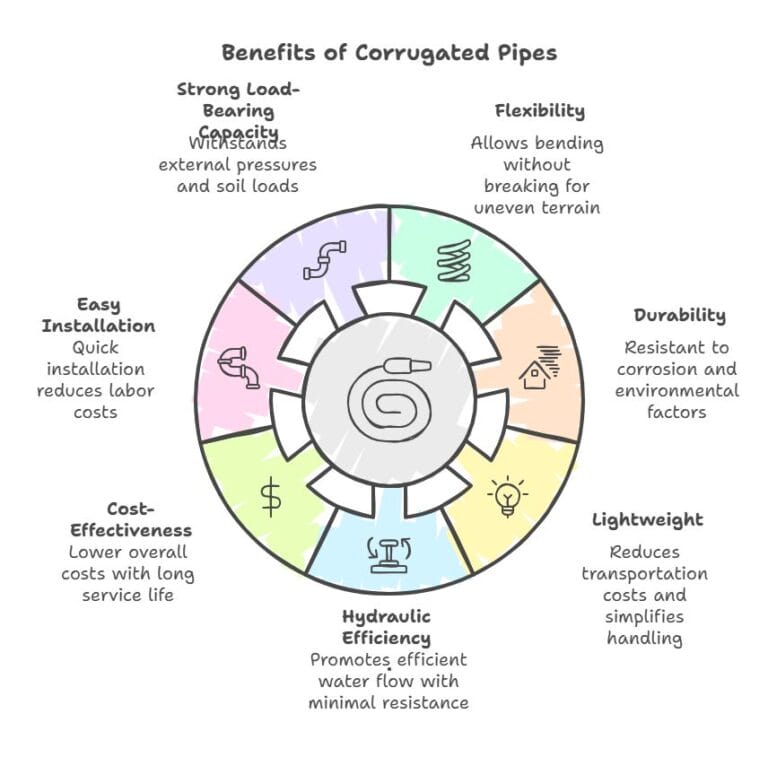

Advantages of Corrugated Pipes

Corrugated pipes offer several benefits over traditional piping materials, including:

- Flexibility: Their corrugated design allows for bending and maneuvering around obstacles without compromising the integrity of the pipe.

- Strength and Durability: Made from high-density polyethylene (HDPE) or other robust materials, corrugated pipes can withstand high pressure and harsh environmental conditions.

- Lightweight: Easier to transport and install compared to heavier alternatives like concrete or metal pipes.

- Cost-Effectiveness: Lower installation and maintenance costs due to their lightweight and long-lasting nature.

- Environmental Benefits: Recyclable materials and reduced need for repairs minimize environmental impact.

Applications in Indian Sewage Systems

Corrugated pipes are used in various sewage management applications in India, including:

- Stormwater Drainage: Efficiently manages large volumes of rainwater, preventing flooding in urban areas.

- Wastewater Conveyance: Transports sewage from residential, commercial, and industrial areas to treatment plants.

- Subsoil Drainage: Improves soil stability and prevents waterlogging in agricultural regions.

- Culverts and Cross-Drainage: Facilitates water flow under roads and railways, ensuring infrastructure safety and longevity.

Installation and Maintenance

The installation process for corrugated pipes is straightforward, involving:

- Site Preparation: Clearing and leveling the area where the pipes will be laid.

- Trenching: Digging trenches to accommodate the pipes, considering the necessary slope for gravity-assisted flow.

- Laying the Pipes: Placing the pipes in the trenches and connecting them using appropriate fittings.

- Backfilling: Covering the pipes with soil and compacting it to ensure stability.

Maintenance is minimal, often limited to periodic inspections and cleaning to prevent blockages.

Case Studies in Indian Cities

Several Indian cities have successfully implemented corrugated pipes in their sewage systems. For example:

- Mumbai: The city’s stormwater drainage system has seen significant improvements in flood prevention due to the use of corrugated pipes.

- Delhi: Upgraded wastewater conveyance networks have enhanced sanitation and reduced sewage overflows.

- Bangalore: Subsoil drainage systems using corrugated pipes have mitigated waterlogging issues in agricultural zones.

Comparison with Traditional Pipes

The table below highlights the key differences between corrugated pipes and traditional piping materials:

| Feature | Corrugated Pipes | Traditional Pipes (Concrete/Metal) |

| Flexibility | High | Low |

| Strength | Durable and resilient | Strong but prone to corrosion/cracking |

| Weight | Lightweight | Heavy |

| Cost | Lower installation and maintenance costs | Higher installation and maintenance costs |

| Environmental Impact | Eco-friendly, recyclable | Higher environmental footprint |

Choose ITIB India for Corrugators

When it comes to corrugated pipes, ITIB India stands out as a leader in manufacturing and supplying high-quality corrugators. With years of expertise and a commitment to innovation, ITIB India provides reliable and efficient solutions tailored to meet the specific needs of Indian sewage systems.

Contact ITIB India today to learn more about how our corrugators can enhance your sewage infrastructure projects.

By understanding the critical role that corrugated pipes play in the efficient management of sewage systems, we can make informed choices that benefit both our communities and the environment.