Essential Parts of A Single Wall Corrugated Pipe Machine

The main parts of a forming machine used in the production of single wall corrugated pipes include:

The Corrugator machine for single wall corrugated pipes contains several critical components:

– Forming Molds/Blocks: The molded components that shape the corrugated pipe pattern. Available in common sizes like 20mm, 25mm, 32mm. A typical machine has several moulds depending on the shape and diameter of pipe produced.

– Rollers: Strategically positioned rollers guide and support the pipe during forming. Help create uniform corrugations.

– Adjustment Mechanism: Allows fine-tuning of pressure, speed, temperature and other parameters. Ensures quality pipes.

– Control Panel: Centralized interface to monitor and control the machine. Enables adjustments and automation.

The specialized molds, rollers, adjustment mechanism and control panel work together to create high quality single wall corrugated pipes efficiently. Component design and configuration varies across manufacturers and pipe requirements.

Part 1: Forming Molds/Blocks

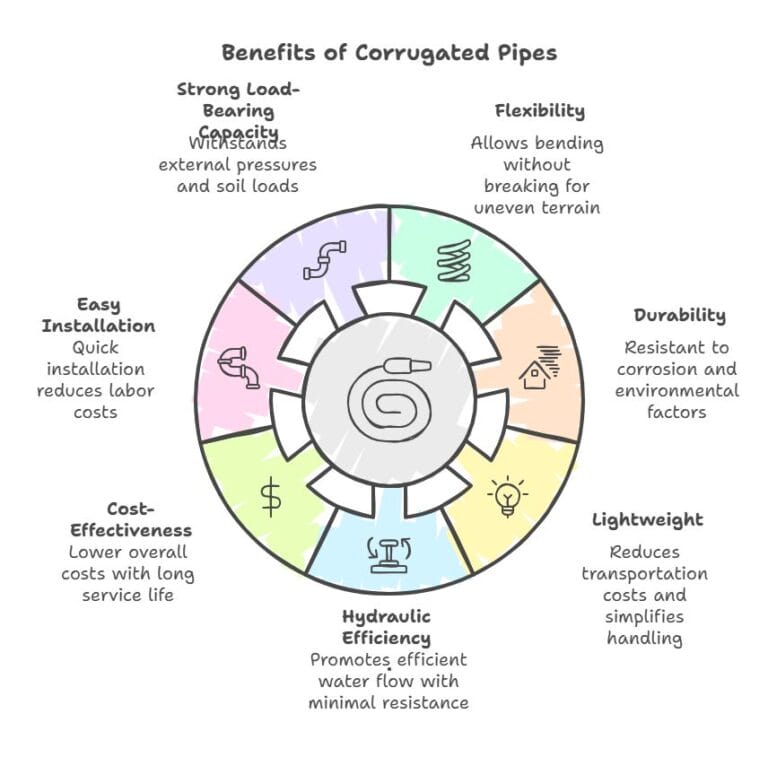

The corrugated design of single wall corrugated pipes is created using specially shaped molds during production. These molds give the pipes their iconic ridges and valleys that make them strong and flexible.

The molds are carefully engineered from durable materials like steel to maintain accuracy through repeated use. They are custom-made to match the exact size specifications of the pipes. For a 32mm pipe, a 32mm mold would be utilized.

In the manufacturing process, the molds are strategically positioned in the forming machine. As the pipe material passes through, it is pressed into the molds, imprinting the corrugated pattern. The controlled pressure ensures uniform, consistent corrugations along the entire length of the pipe.

Since the molds are interchangeable, manufacturers can easily switch between molds for different pipe diameters. This allows flexibility in meeting varying customer size requirements with the same forming equipment. The versatility of the molds facilitates efficient production of a wide range of single wall corrugated pipes.

Part 2: Rollers

Rollers are a key component of the forming machine used to manufacture single wall corrugated pipes. As the pipe material passes through the machine, the rollers guide it and provide crucial support during the shaping process.

Strategically positioned along the pipe’s path, the rollers apply calculated pressure to maintain the proper form. This prevents distortion as the corrugated design is imprinted. The rollers help mold the material, pressing it into the corrugated pattern between them.

By adjusting the number and spacing of the rollers, different corrugation sizes and designs can be achieved. The rollers also ensure consistency, using even pressure distribution to avoid irregularities in the patterning. This results in uniform corrugations that optimize the pipe’s structural integrity.

Designed for smooth function, the rollers minimize friction and wear. Durable materials withstand the high forces involved, while components like bearings facilitate easy rotation. This enables efficient production with reduced maintenance needs.

In summary, the strategic roller mechanisms guide the pipe material and are instrumental in achieving consistent, high-quality corrugated pipe products. Their specialized engineering directly impacts the forming process and the quality of the end product.

Part 3: Adjustment Mechanism

The adjustment mechanism is a critical component of the corrugated pipe forming machine. It enables precise control over the production process to achieve high quality single wall corrugated pipes.

Through the adjustment mechanism, operators can fine-tune key parameters including pressure, speed, temperature, and mold alignment. Controlling the pressure applied to the pipe allows for optimizing the depth and shape of corrugations. Adjusting the machine speed affects productivity and quality control. Proper mold alignment ensures uniform corrugation formation along the entire length of the pipe. Temperature adjustment is critical for softening the thermoplastic material appropriately.

The adjustment mechanism is typically operated through a control panel interface. This allows the operator to monitor and modify parameters efficiently to optimize the forming process. With real-time control over key variables, the adjustment mechanism empowers operators to meet quality standards and maintain consistent corrugation patterns batch after batch.

Overall, the adjustment mechanism provides vital precision and flexibility in the corrugated pipe production process. By enabling fine-tuning of pressure, speed, temperature, and alignment, it allows operators to achieve the desired structural integrity, flexibility, and quality in the finished single wall corrugated pipes. The mechanism is an indispensable component of the forming machine.

Part 4: Control Panel

Corrugator Machine relies on a central control panel for monitoring and adjusting the production process. This interface enables operators to maintain optimal conditions and ensure smooth, efficient pipe production.

The control panel displays real-time readings of key parameters like temperature, pressure, speed, and machine status. Operators can quickly identify any abnormalities and take corrective action. Adjustments to pressure, speed, temperature, and mold alignment are made easily through the control panel for precision control.

Production specifications including pipe size, corrugation patterns, and length are input into the control panel. This allows the machine to be programmed for automated production per the requirements, increasing efficiency and consistency.

Safety features built into the control panel like emergency stops and fault detection alert operators about dangerous conditions or malfunctions. This promotes a safe working environment.

Modern touchscreen interfaces provide intuitive control for quick navigation and access to settings. The user-friendly design enables operators to monitor and modify parameters efficiently.

The corrugator machine for producing single wall corrugated pipes contains several key components that work in unison to create high-quality products. The forming molds imprint the iconic corrugated pattern into the pipe material. Strategically positioned rollers guide and support the pipe through the shaping process. For thermoplastic materials, an integrated heating system softens the material for easier molding.

Fine-tuning of the process is enabled by the adjustment mechanism for parameters like pressure, speed, and temperature. The control panel provides a central interface to monitor conditions and implement adjustments for optimal efficiency.

Together, these components enable precision patterning, consistent quality, and efficient production of corrugated pipes. They allow manufacturers to meet industry standards and customer specifications cost-effectively. The versatility of the corrugator machine facilitates manufacturing strong, reliable corrugated pipes for diverse applications in construction, agriculture, drainage systems, and more.

By leveraging the capabilities of the forming molds, rollers, adjustment mechanism, and control panel, manufacturers can optimize all aspects of the production process. The innovative integration of these components has made modern corrugator machines instrumental in the efficient mass production of quality single wall corrugated pipes.