Complete Turnkey Solution for Single Wall and Double Wall Corrugated Pipes

When it comes to manufacturing corrugated pipes, businesses require a comprehensive and reliable solution that ensures both efficiency and quality. ITIB India stands at the forefront of the industry, offering a complete turnkey solution for Single Wall and Double Wall corrugated pipe production. With cutting-edge equipment, precision engineering, and a commitment to delivering outstanding results, ITIB India provides manufacturers with everything they need to succeed.

The Key Components of ITIB India’s Turnkey Solution

ITIB India’s turnkey solution for corrugated pipes includes the following essential components:

1. Extruder

At the heart of any corrugated pipe manufacturing line is the extruder. We provide extruders that are designed for optimal performance, ensuring a consistent and smooth extrusion of thermoplastics. These extruders feature advanced control systems that allow precise temperature management and material feed, resulting in high-quality pipes with uniform thickness and durability

2. Die Heads

Die heads are responsible for shaping the plastic material into the desired pipe form. Our die heads are engineered to provide optimal material flow and uniform distribution, ensuring the production of high-quality pipes. These die heads are designed for easy maintenance and quick changeovers, reducing downtime and enhancing productivity.

3. Corrugator

The corrugator is critical in forming the corrugated structure of the pipe, which provides flexibility and strength. ITIB India’s corrugators are engineered for efficiency, delivering high-speed production while maintaining precise control over pipe dimensions. These machines are capable of producing both single-wall and double-wall corrugated pipes, making them versatile for a wide range of applications, from drainage systems to electrical conduits.

4. Die Moulds

Precision is key in the manufacturing of corrugated pipes, and ITIB India’s die moulds are designed for the highest dimensional accuracy of the Final Product. These moulds are crafted with high accuracy to produce pipes with consistent wall thickness, diameter, and corrugation profile. ITIB India offers a wide range of die moulds to accommodate different pipe sizes and specifications, ensuring versatility in production capabilities. Critical Shapes require Vacuum System to ensure perfect shape in case of small diameters or in case of uneven profile Diameters.

5. Cooling Tanks

Effective cooling is crucial to maintaining the structural integrity of the pipes. We can provide state-of-the-art cooling tanks that rapidly and evenly cool the extruded pipes, ensuring that they retain their shape and strength. These tanks are designed to maximize the cooling efficiency while minimizing energy consumption, making the production process more cost-effective.

6. Puller

The puller plays an essential role in drawing the pipe through the manufacturing process, ensuring smooth and consistent production. We provide pullers that are designed for accuracy and stability, maintaining the correct tension on the pipes as they move through the corrugator. This results in a uniform corrugated structure and prevents any distortions during the cooling process.

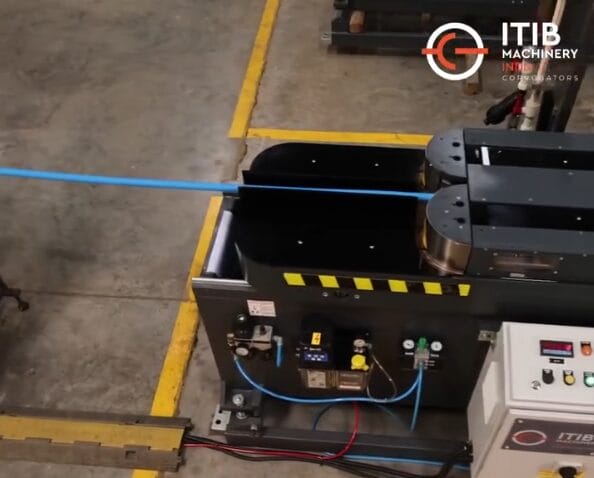

7. Coilers

Once the pipes have been extruded and cooled, they need to be coiled for easy handling and storage. ITIB India’s coilers are built to handle pipes of various sizes and lengths, ensuring that the coiling process is smooth and efficient. These machines are designed to minimize manual handling, improving safety and reducing labor costs in the production facility.

Why Choose ITIB India’s Turnkey Solution?

With ITIB India’s complete turnkey solution, manufacturers can streamline their corrugated pipe production process from start to finish. The seamless integration of each component ensures maximum efficiency, minimal waste, and consistent product quality. Whether you’re producing pipes for drainage, sewage, electrical, automotive, sanitary or telecommunications applications, ITIB India’s advanced technology and engineering expertise offer unmatched reliability and performance.

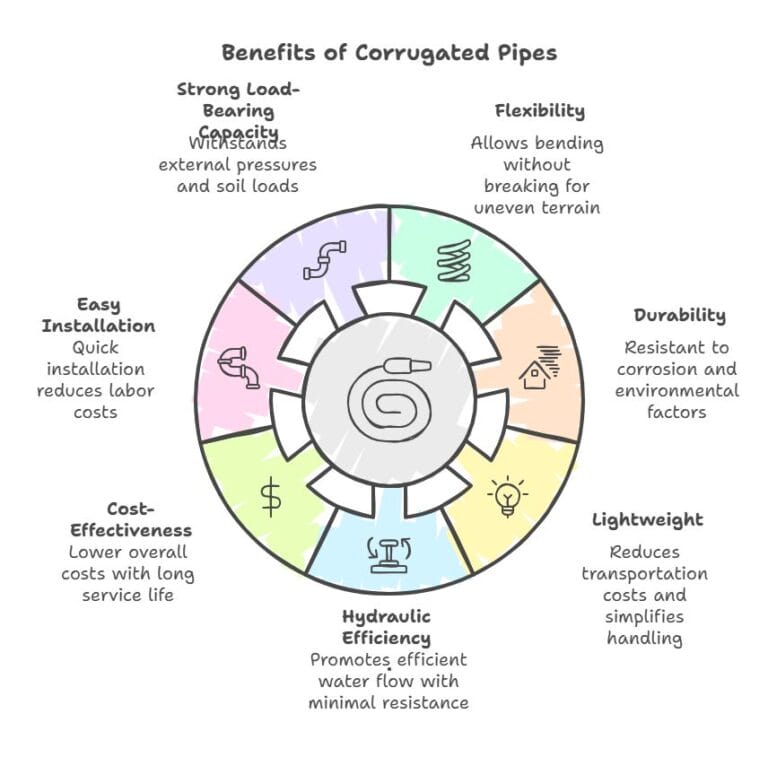

Benefits of ITIB India’s Turnkey Solution:

- End-to-end integration: Each piece of equipment is synchronised to work harmoniously in tandem, reducing the risk of errors and downtime.

- Customizable solutions: ITIB India offers equipment for various pipe sizes and materials, allowing manufacturers to tailor their production lines to specific needs.

- Energy efficiency: With advanced cooling systems and optimized machinery, ITIB India helps manufacturers reduce energy consumption and operational costs.

- High-quality output: Precision engineering ensures that every pipe produced meets industry standards for strength, flexibility, and durability.

Conclusion

ITIB India provides a complete, high-performance solution for Single Wall and Double Wall corrugated pipe manufacturing. From the extruder to the coiler, each component is designed with efficiency, reliability, and quality in mind. By choosing ITIB India’s turnkey solution, manufacturers can enhance their production processes, reduce costs, and deliver top-tier products to their customers.

For more information on how ITIB India can transform your corrugated pipe production, contact us today to learn more about our turnkey solutions.